Jet Thruster Technical Manuals

Before you start: Quick Start manual - select your language

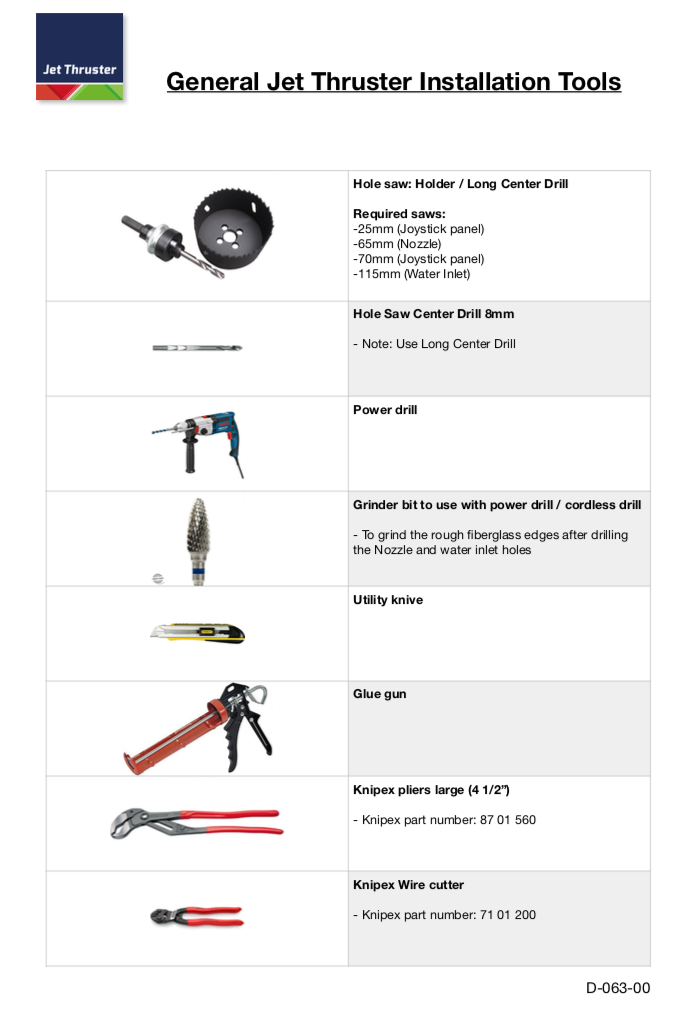

When you have a question about installation, maintenance or repair:

Informative video's

Winterising your Jet Thruster system

In this video we explain how you can easily winterise your Jet Thruster system with help of compressed air

Installation example

In this video we show the installation of a JT50 Jet Thruster system in a 36ft Sail Yacht

Installation example

In this video we show the installation of a JT50 Jet Thruster system in a Green Line Hybrid Motor Yacht

NEW: Online Jet Thruster Store

Ordering a Jet Thruster or Jet Thruster components has never been more easy.

Visit our online store and place your: We ship Express world wide from stock

- OEM SALES

- All Systems

- Upgrade packages

- Spare Parts

Frequently Asked Questions: Composite parts

Need more info? Just ask!

Need more info? Just ask!

We understand you might have technical questions. Just ask them!

Call us and ask your question, or

upload a picture of your boat at our contact form at the home page. Our team will contact you with information