About the Jet Thruster Team

Holland Marine Parts in Dordrecht, the Netherlands, manufactures the Jet Thruster. Owner-manager Henry Kroeze and Sales Director Pieter Cats are the familiar faces of the company.

The Jet Thruster is a unique system that uses water pressure to easily manoeuvre pleasure boats from 25-60 ft. Since 2010 It finds its way from Dordrecht, The Netherlands, to customers all over the world.

The current Jet Thruster has a comparatively short history, contrary to Henry Kroeze’s, who has over forty years’ experience in metalworking and plastic processing industry.

In addition Henry Kroeze has vast experience as an entrepreneur in the maritime sector. In this capacity he supplies, among other things, motor components to shipbuilders at home and abroad.

One of Kroeze’s traits is that he never ever stops at half measures. He strives for perfection, and this was evident in the development of the Jet Thruster.

In 2020 Holland Marine Parts celebrated it's 10-Years anniversary

Development:Composite Parts

The next level in marine Technology

"We keep developing better products"

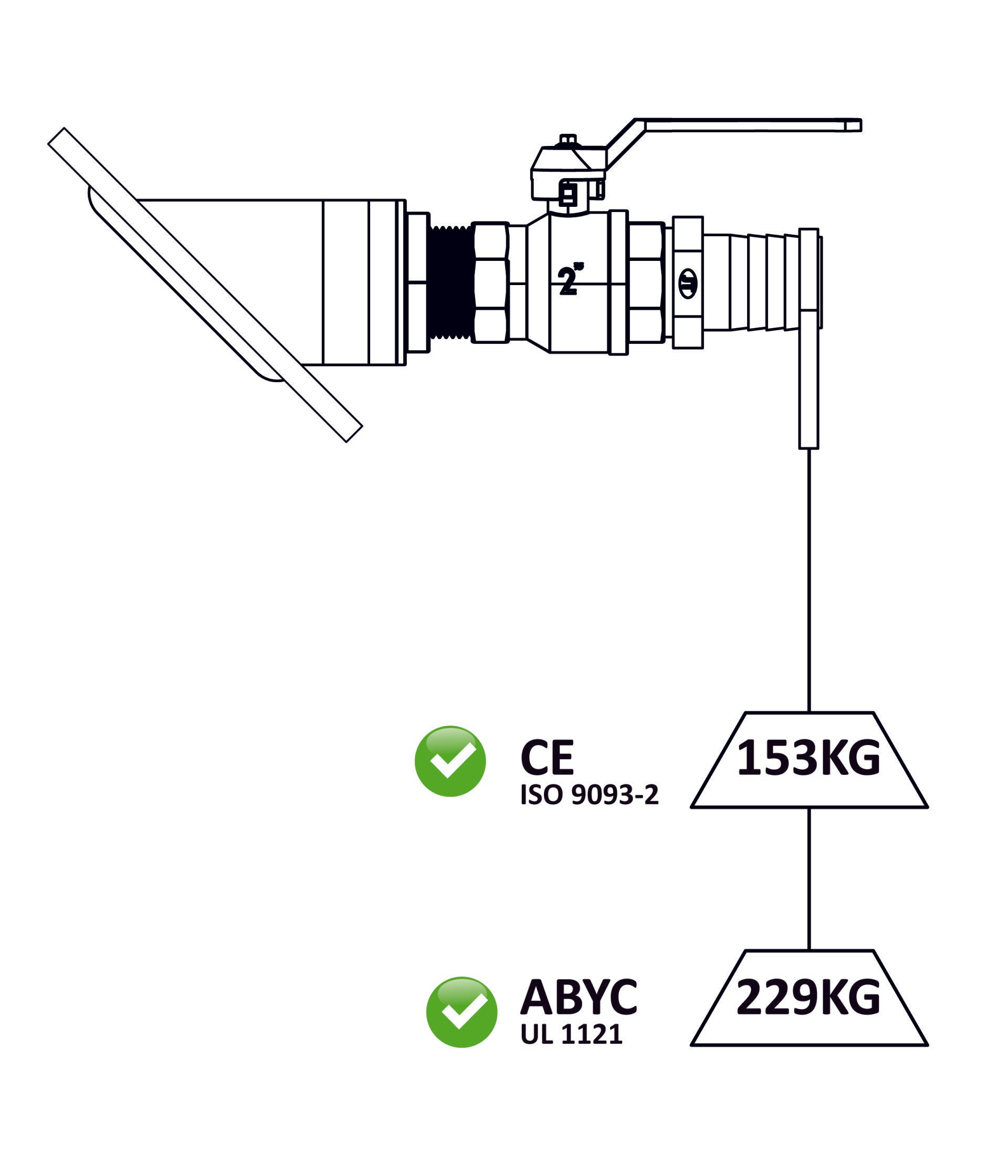

Testing and certification